Description

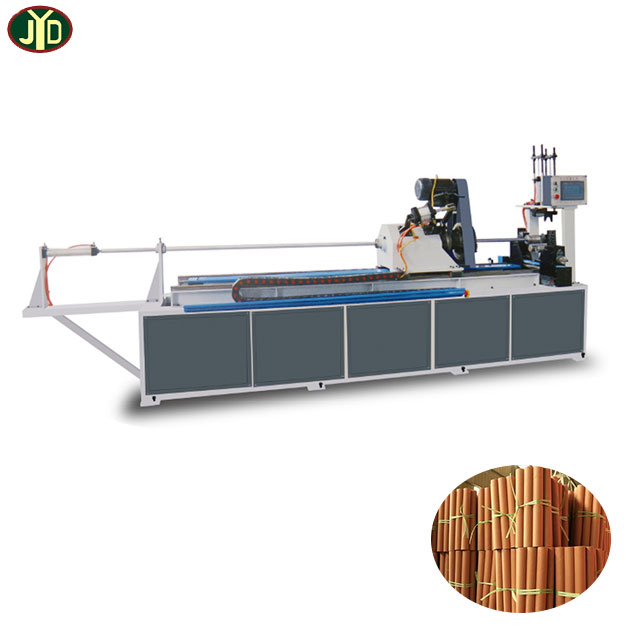

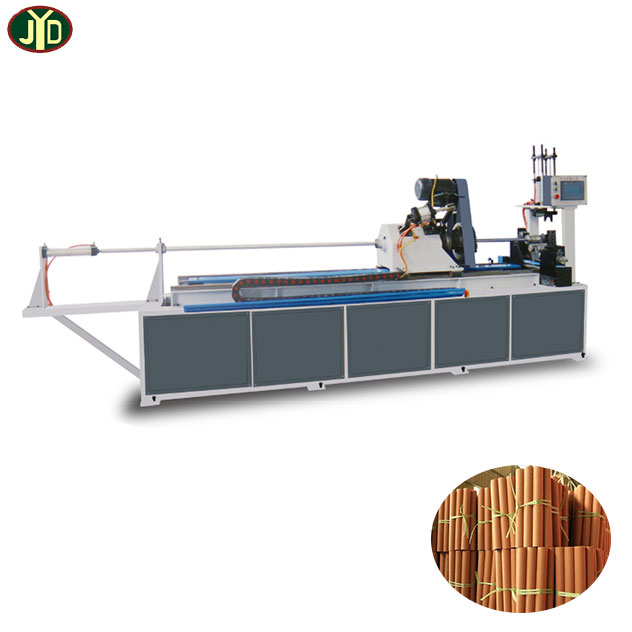

Paper Tube Fine Cutting Machines Introduction

The auto paper tube fine cutting machine is a highly advanced piece of equipment designed for precision cutting of fine paper core tubes. This machine is ideal for various industries such as packaging, textiles, and printing, where accuracy and speed are paramount. Engineered for maximum efficiency and reliability, it significantly enhances productivity while maintaining top-notch quality. With its fully automated operation and user-friendly interface, this machine seamlessly integrates into any production line, providing an invaluable asset for manufacturers.

Paper Tube Fine Cutting Machines Parameter

| Diameter | Φ76-152(mm) |

| Thickness | 3-15(mm) |

| Cutting Length | 20-3200(mm) |

| Number Of Cutter | 1 set |

| Working Pressure | 0.6Mpa |

| Control Mode | CNC |

| Motor Power | 7.75kw |

| Operators | 1 |

| Host Machine: Length * Width * Height | 8700mm*1900*1600mm |

| Area Covered | 3600*1700mm |

| Knife Specification | 2*100*22mm |

| Total Weight | 1500kg |

Paper Tube Fine Cutting Machines Structure

The paper tube fine cutting machines is constructed with several key components that ensure superior performance:

Shaftless Design:

The innovative shaftless design facilitates easy loading and unloading of paper cores, increasing efficiency and reducing setup time.

Precision Cutting Blades:

High-quality cutting blades guarantee clean and accurate cuts, minimizing waste and enhancing product quality.

Automated Feeding System:

The automatic feeding system streamlines the process by feeding paper tubes into the cutting area without manual intervention, significantly boosting productivity.

Adjustable Cutting Parameters:

Easily adjustable settings enable customization of tube lengths and diameters, catering to diverse production needs.

Robust Frame Construction: Made from durable materials, the robust frame ensures stability and long-term reliability, even under continuous operation.

Safety Mechanisms:

Enhanced safety features, including emergency stop functions and protective guards, ensure a safe working environment for operators.

User-Friendly Control Panel:

The intuitive control panel allows operators to set parameters and monitor the cutting process with ease, reducing the likelihood of errors.

Paper Tube Fine Cutting Machines Differences

- Provides faster setup times and smoother operation due to the absence of a central shaft. This results in higher overall efficiency.

- Offers greater versatility in handling different core sizes and diameters. This adaptability makes shaftless machines more suitable for varied production needs

- Generally easier to maintain due to fewer moving parts. The reduced complexity enhances durability and reliability.

- Although the initial investment may be higher, the long-term savings from reduced maintenance and increased productivity can offset the initial cost.

- More compact design allows for better space utilization and easier integration into existing production setups.

Paper Tube Fine Cutting Machines Applications

The versatility of the auto paper tube fine cutting machines makes it suitable for a wide range of applications across various industries:

Packaging Industry: Ideal for producing precisely cut paper cores used in packaging materials, ensuring products are securely and neatly packaged.

Textile Industry: Perfect for cutting paper cores that serve as cores for fabric rolls, ensuring uniform lengths and smooth edges.

Printing Industry: Ensures exact core lengths for printing applications, aiding in the production of high-quality printed materials.

Tape and Label Manufacturing: Suitable for producing cores for tapes and labels, facilitating efficient winding and unwinding.

Paper Products Manufacturing: Useful for cutting paper cores used in various paper products, including rolls of paper and labels.

The paper core tube cutting machine’s move to a shaftless design offers many advantages over traditional shaft-based models. These advantages include easier loading and unloading, enhanced flexibility, increased production speeds, reduced maintenance, and greater space efficiency. Understanding these advantages and differences is critical for businesses looking to improve their production processes and maintain a competitive edge. By investing in shaftless technology, companies can achieve greater efficiency, versatility, and cost savings in the long run.

Customer Support:

When you purchase our auto paper tube fine cutting machines, you will enjoy comprehensive customer support services, including:

Professional installation and commissioning: ensure the normal operation of the equipment.

Technical training: provide comprehensive training for your operators to ensure that they can operate the auto paper tube fine cutting machines.

After-sales service: fast-response after-sales support to solve your worry.