Description

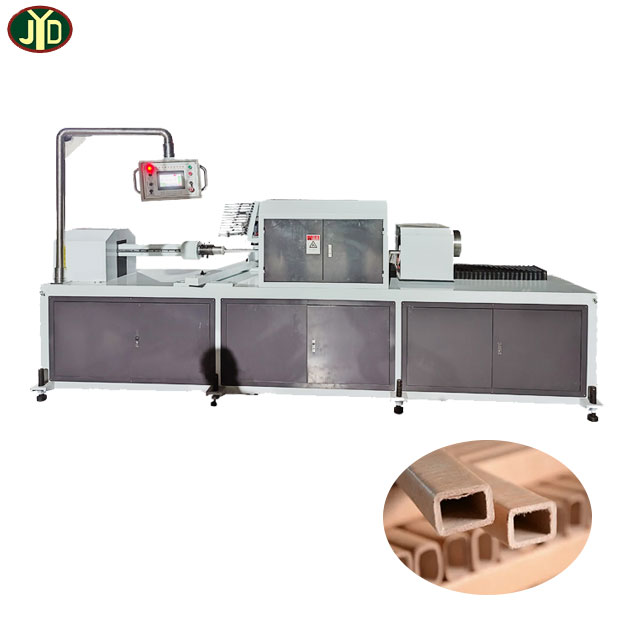

Spiral Paper Tube Winding Machine Introduction

To begin with, the automatic spiral paper tube winding machine is designed to produce square paper cores, which are essential for a variety of packaging applications. Unlike traditional round cores, square paper cores offer enhanced stacking efficiency and stability. This makes them ideal for storing and transporting products that need to remain upright and aligned.

One of the primary advantages of this machine is its automation capabilities. Traditional core winding processes often require significant manual labor, which can lead to inconsistencies and inefficiencies. However, the spiral paper tube winding machine automates these processes, ensuring uniformity and precision in every core produced. Consequently, this reduces labor costs and minimizes the risk of human error.

Spiral Paper Tube Winding Machine Parameter

| Model | JYD-820 | JYD-1100 |

| Maximum jumbo roll diameter | 1300mm | 1300mm |

| Maximum jumbo roll width | 800mm | 1080mm |

| Square tube width range | 240-400mm | 240-400mm |

| Round tube diameter | 240-450mm | 240-450mm |

| Paper weight | 280-360gsm | 280-360gsm |

| Gluing method | Single layer | Single layer |

| Square tube produce speed | 150pcs/h | 150pcs/h |

| Round tube produce speed | 200pcs/h | 200pcs/h |

| Power | 10.5KW | 12KW |

| Weight | 2000kgs | 3000kgs |

| Dimension | 4200x2400x1500mm | 4220x2420x1500mm |

Spiral Paper Tube Winding Machine Advantage

Enhancing Efficiency with Advanced Technology

The spiral paper tube winding machine incorporates advanced technology to streamline the production process. For instance, it utilizes programmable logic controllers (PLCs) to manage and monitor the winding operations. This allows for real-time adjustments and optimizations, ensuring that the machine operates at peak efficiency.

In addition to automation, the machine’s parallel winding mechanism is a key feature that sets it apart. Traditional winding machines often wind cores sequentially, which can be time-consuming. In contrast, the parallel winding mechanism enables the machine to produce multiple cores simultaneously. As a result, production rates are significantly higher, meeting the demands of high-volume packaging operations.

Sustainability and Environmental Benefits

Transitioning to environmental considerations, the spiral paper tube winding machine supports sustainability in several ways. Firstly, it is designed to work with recyclable and biodegradable paper materials. This reduces the environmental impact associated with plastic or metal cores. Secondly, the precision of the machine minimizes material wastage, ensuring that resources are used efficiently.

Furthermore, many manufacturers are now prioritizing eco-friendly packaging solutions. The ability to produce paper cores that can be easily recycled aligns with these sustainability goals. Consequently, adopting this machine can enhance a company’s reputation as an environmentally responsible organization.

Versatility and Customization

Another notable benefit of the spiral paper tube winding machine is its versatility. It can be customized to produce cores of various sizes and thicknesses, catering to different packaging requirements. Whether it’s for heavy-duty industrial use or delicate consumer goods, this machine can adapt to meet diverse needs.

The machine’s user-friendly interface makes it easy to operate. Operators can quickly adjust settings and parameters to accommodate different production specifications. This flexibility is particularly valuable in dynamic manufacturing environments where product lines may frequently change.

Economic Advantages

From an economic perspective, investing in an spiral paper tube winding machine can lead to substantial cost savings. While the initial investment might be significant, the long-term benefits outweigh the costs. Reduced labor expenses, lower material wastage, and increased production efficiency contribute to a higher return on investment.

The machine’s durability and low maintenance requirements further enhance its economic appeal. Built with high-quality materials and components, it can withstand continuous operation without frequent breakdowns. This reliability ensures uninterrupted production, which is crucial for meeting tight deadlines and maintaining customer satisfaction.

Spiral Paper Tube Winding Machine Application

Food packaging: storage and transportation of foods such as grains, flour, and candy.

Industrial products: packaging of chemical products, powdered materials, etc.

Retail packaging: packaging of retail goods such as clothing, shoes, hats, and toys.

Gift packaging: can be designed into high-end gift boxes for packaging gifts.

Storage: used to store documents, books, and other items at home or in the office.

Customer Support:

When you purchase our automatic spiral paper tube winding machine, you will enjoy comprehensive customer support services, including:

Professional installation and commissioning: ensure the normal operation of the equipment.

Technical training: provide comprehensive training for your operators to ensure that they can operate the automatic spiral paper tube winding machine.

After-sales service: fast-response after-sales support to solve your worry

In conclusion, the automatic spiral paper tube winding machine is a transformative innovation in the packaging industry. Its ability to automate and optimize the core winding process offers numerous benefits, including increased efficiency, sustainability, versatility, and cost savings. As the demand for high-quality, eco-friendly packaging solutions continues to rise, this machine is poised to play a pivotal role in shaping the future of packaging technology.