In the packaging industry, protecting products during shipping and storage is crucial. One effective solution is using paper corner boards, and the machines that manufacture them play a vital role. This blog explores the importance of paper corner board machines, how they work, and their benefits. Understanding these machines can help businesses enhance packaging efficiency and product protection.

What Are Paper Corner Boards?

Paper corner boards are essential packaging materials designed to reinforce and protect the corners of products. These boards are commonly used in industries like electronics, furniture, and logistics. They help prevent damage during transportation and storage. Made from layers of recycled paper, these boards are both eco-friendly and cost-effective.

Paper Corner Board Machine Functions

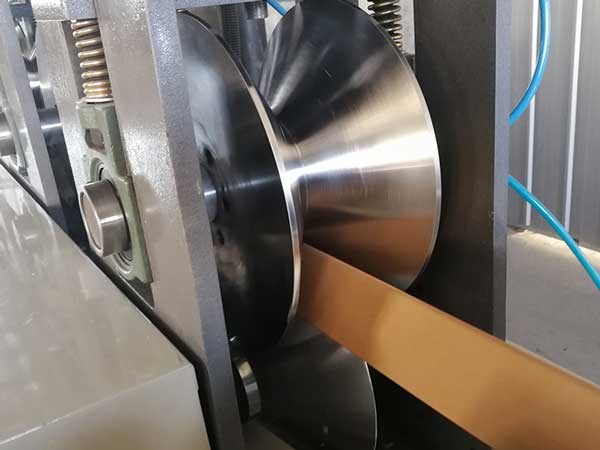

A paper corner board machine automates the production of these protective boards. It takes in raw materials, such as kraft paper and adhesives, and processes them into finished products. The machine typically includes several components: an unwinding unit, a glue application system, a forming section, and a cutting unit. These components work together to produce consistent, high-quality corner boards.

Paper Corner Board Machine Benefits

Efficiency and Cost-Effectivenes

One significant advantage of using a paper corner board machine is increased production efficiency. These machines can produce a large quantity of boards in a short time, reducing labor costs and material wastage. Additionally, they allow for precise control over the dimensions and quality of the boards, ensuring consistency.

Customization and Versatility

Paper corner board machines offer customization options, enabling businesses to produce boards of various sizes and shapes. This flexibility makes them suitable for protecting different products, from small electronics to large furniture items. Moreover, the use of recycled materials makes these machines an eco-friendly choice, aligning with sustainable business practices.

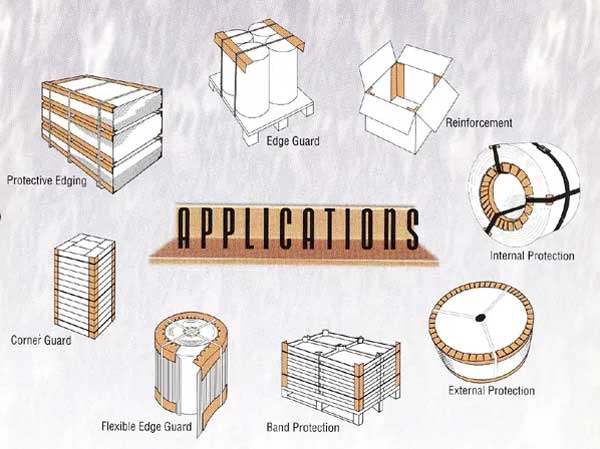

Paper Corner Boards Applications

Paper corner boards are widely used across various industries to protect products. In the electronics sector, they safeguard fragile items like televisions and computer monitors. Furniture manufacturers use them to reinforce packaging and prevent damage to tables, chairs, and other products. Additionally, logistics companies rely on these boards to secure and stabilize palletized goods during transportation.

How to Choose the Right Paper Corner Board Machine

Selecting the right paper corner board machine involves considering several factors. First, assess your production needs, including the required capacity and board dimensions. It’s also essential to consider the machine’s ease of use, maintenance requirements, and energy efficiency. Researching leading brands and consulting with industry experts can help make an informed decision.

Maintenance and Best Practices

Proper maintenance of a paper corner board machine ensures its longevity and optimal performance. Regularly inspect the machine for wear and tear, and clean the components to prevent build-up of adhesives or dust. Following the manufacturer’s guidelines for routine maintenance can prevent unexpected breakdowns and extend the machine’s lifespan. Additionally, training operators on best practices can improve efficiency and safety.

Environmental Impact and Sustainability

The use of paper corner board machines contributes to sustainability in the packaging industry. By using recycled paper as a primary material, these machines reduce the need for virgin resources. Moreover, businesses can implement eco-friendly practices, such as using water-based adhesives and energy-efficient equipment, to minimize their environmental footprint.

Future Trends in Paper Corner Board Manufacturing

The future of paper corner board manufacturing looks promising, with advancements in technology and materials. Automation and digitalization are expected to improve production efficiency and reduce costs. Additionally, innovations in eco-friendly materials will further support sustainability initiatives. As market demand for sustainable packaging solutions grows, the paper corner board industry is poised for continued expansion.

Conclusion

Paper corner board machines are indispensable in the packaging industry, offering efficiency, cost-effectiveness, and environmental benefits. By understanding how these machines work and their applications, businesses can enhance their packaging processes and product protection. As the industry evolves, embracing new technologies and sustainable practices will be key to staying competitive.