Description

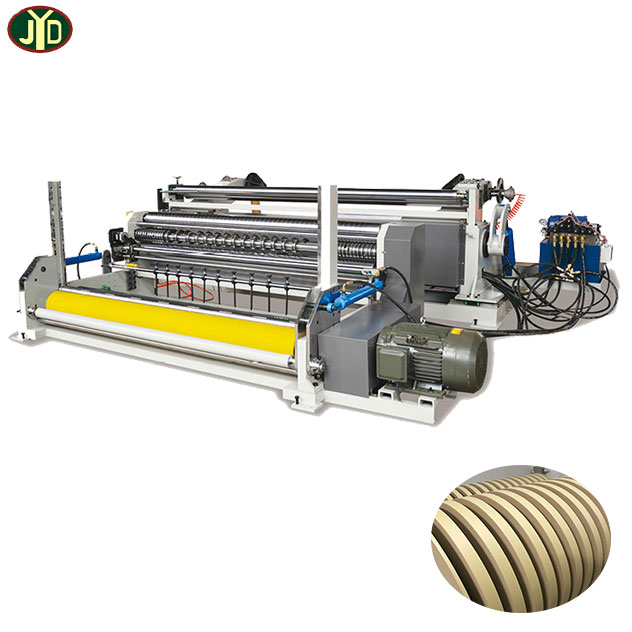

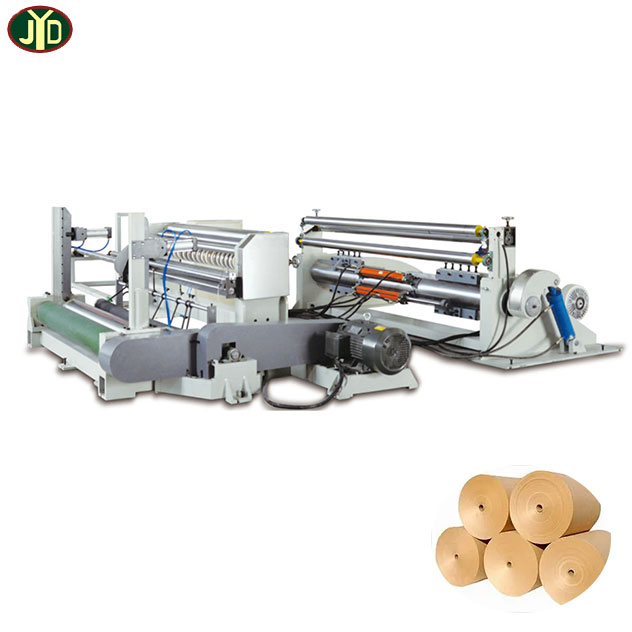

Paper Slitting And Rewinding Machine Introduction

The high speed kraft paper slitting and rewinding machine is a state-of-the-art device designed for efficiency and precision in the paper industry. This machine specializes in slitting large kraft paper rolls into smaller, more manageable sizes, while simultaneously rewinding them into neat rolls. Ideal for high-volume production environments, it boasts advanced technology that ensures smooth operation and minimal downtime. Crafted from high-quality materials, this machine guarantees durability and long-term reliability. By incorporating this machine into your production line, you can significantly enhance your operational efficiency and product quality.

Paper Slitting And Rewinding Machine Parameter

| Base Paper Width | 2500(mm) |

| Diameter Of Base Paper | 1200(mm) |

| Rewinding Diameter | 1200(mm) |

| Slitting Width | >35(mm) |

| Base Paper Weight | 80-600g |

| Number Of Cutters | 18pcs |

| Slitting Speed | 1-300(m/min) |

| Speed Control | Frequency control |

| Main Power | 15kw |

| Total Weight | 5900kg |

| Tension Adjustment | Automatic magnetic powder brake |

| Paper Loading Method | Hydraulic Shaftless support |

| Unloading Method | Hydraulic blanking |

| Winding Method | Gas up outside the closed |

| Knife Adjustment Method | CNC tool adjustment |

Paper Slitting And Rewinding Machine Features

The high speed kraft paper slitting and rewinding machine comes with a plethora of features designed to meet the diverse needs of paper processing businesses. Here are some key features:

High-Speed Operation:

Capable of operating at impressive speeds, this machine significantly reduces processing time, thereby increasing productivity.

Precision Slitting:

Equipped with advanced slitting tools, it ensures clean and precise cuts, minimizing waste.

Automatic Tension Control:

This feature maintains consistent tension during both slitting and rewinding processes, ensuring uniform roll quality.

User-Friendly Interface:

The intuitive control panel allows operators to easily set parameters and monitor the process, reducing the likelihood of errors.

Robust Construction:

Built with durable components, the machine withstands rigorous use and requires minimal maintenance.

Safety Mechanisms:

Enhanced safety features protect operators, ensuring a safe working environment.

Energy Efficient:

Designed to consume less power, the machine helps reduce operational costs.

Versatile Applications:

Suitable for various kraft paper grades, it can handle a wide range of slitting and rewinding requirements.

Paper Slitting And Rewinding Machine Applications

The high speed kraft paper slitting and rewinding machine is versatile, catering to numerous industries and applications. Here are some of its primary applications:

Packaging Industry:

Essential for converting large kraft paper rolls into smaller ones used in packaging applications, such as wrapping, boxing, and bag making.

Printing Industry:

Ideal for preparing kraft paper rolls for printing presses, ensuring they are the right size and tension for high-quality print outputs.

Paper Product Manufacturing:

Used in the production of various paper products, including paper bags, envelopes, and corrugated materials.

Label Production:

The machine can be used to produce kraft paper labels, which are essential for various labeling applications across multiple industries.

Industrial Applications:

Suitable for creating kraft paper rolls used in protective coverings, insulation, and other industrial applications.

Incorporating the high speed kraft paper slitting and rewinding machine into your production line brings numerous advantages. Firstly, its high-speed operation means more output in less time, which is crucial for meeting large orders. Moreover, precision slitting reduces material waste, translating to cost savings. Automatic tension control ensures the rolls produced are of high quality, thus minimizing rejects and rework. Additionally, the machine’s user-friendly interface allows operators to easily adjust settings and monitor operations, reducing the likelihood of errors.

Customer Support:

When you purchase our high speed kraft paper slitting and rewinding machine, you will enjoy comprehensive customer support services, including:

Professional installation and commissioning: ensure the normal operation of the equipment.

Technical training: provide comprehensive training for your operators to ensure that they can operate the high speed kraft paper slitting and rewinding machine.

After-sales service: fast-response after-sales support to solve your worries.