Description

Cardboard Tube Cutting Machine Introduction

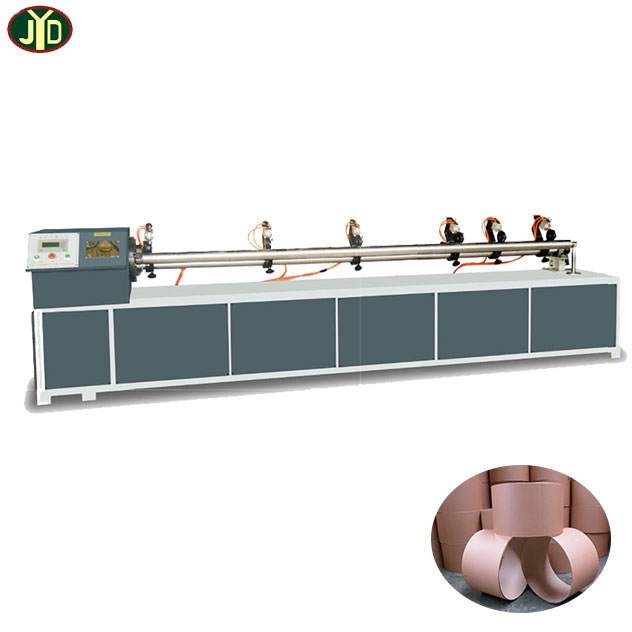

The cardboard tube cutting machine is a revolutionary piece of equipment designed for precise and efficient cutting of fireworks paper tubes. This machine is essential for the fireworks manufacturing industry, where accuracy and speed are crucial. Engineered for optimal performance, it significantly enhances productivity while ensuring high-quality output. With its advanced automation and user-friendly interface, this machine integrates seamlessly into any production line, making it a valuable asset for manufacturers.

Cardboard Tube Cutting Machine Parameter

| Diameter | Φ76-152(mm) |

| Thickness | 3-15(mm) |

| Cutting Length | 120-2700(mm) |

| Number Of Cutter | 6 set (standard ) |

| Working Pressure | 0.6Mpa |

| Control Mode | CNC |

| Motor Power | 0.6kw |

| Operators | 1 |

| Host Machine: Length * Width * Height | 3600mm*700mm*1300mm |

| Area Covered | 3600*1700mm |

| Knife Specification | 2*150*43mm |

| Total Weight | 600kg |

Cardboard Tube Cutting Machine Structure

The cardboard tube cutting machine is built with several key structural components that ensure its superior performance:

CNC Control System:

The advanced CNC control system allows for precise cutting operations, ensuring that each paper tube is cut to the exact specifications.

High-Speed Cutting Blades:

Equipped with durable, high-speed cutting blades, this machine ensures clean and smooth cuts, reducing waste and improving efficiency.

Automatic Feeding System:

The automatic feeding system streamlines the process, feeding paper tubes into the cutting area without manual intervention, thus enhancing productivity.

Adjustable Settings:

Easily adjustable settings enable customization of tube lengths and diameters, catering to various production needs.

Robust Frame:

Constructed from high-quality materials, the robust frame ensures stability and long-term durability, even under continuous operation.

Safety Features:

Enhanced safety mechanisms, including emergency stop functions and protective guards, ensure a safe working environment for operators.

User-Friendly Interface:

The intuitive control panel allows operators to easily set parameters and monitor the cutting process, minimizing errors and downtime.

Cardboard Tube Cutting Machine Applications

The cardboard tube cutting machine is versatile and can be utilized in various applications within the fireworks manufacturing industry:

Fireworks Production: Essential for cutting paper tubes to precise lengths for various types of fireworks, including rockets, shells, and fountains.

Tube Manufacturing: Ideal for producing uniform and accurately cut paper tubes that serve as the foundation for different fireworks products.

Custom Fireworks Design: Perfect for creating custom-sized paper tubes needed for specialized fireworks displays and effects.

Bulk Production: Suitable for high-volume production environments where speed and accuracy are paramount to meet large orders efficiently.

Prototype Development: Useful for developing prototypes of new fireworks designs, ensuring that paper tubes are cut to exact specifications for testing and refinement.

Integrating the cardboard tube cutting machine into your production line offers numerous benefits. Firstly, the CNC control system guarantees precision, ensuring that each cut is accurate and consistent. This high level of precision minimizes waste and enhances product quality. Additionally, the high-speed cutting blades and automatic feeding system significantly increase productivity, allowing you to meet large orders quickly and efficiently.

In conclusion, the cardboard tube cutting machine is an indispensable tool for any fireworks manufacturing operation. Its advanced features and versatile applications make it essential for improving productivity, quality, and safety in your production processes. By investing in this machine, you can enhance your production capabilities and ensure the delivery of high-quality fireworks products to your customers.

Customer Support:

When you purchase our cardboard tube cutting machine , you will enjoy comprehensive customer support services, including:

Professional installation and commissioning: ensure the normal operation of the equipment.

Technical training: provide comprehensive training for your operators to ensure that they can operate the cardboard tube cutting machine.

After-sales service: fast-response after-sales support to solve your worry.