The paper corner board machine can produce paper corners of various shapes, such as V-shaped, U-shaped, flat-plate paper corners, and can also produce paper pallet-shaped paper corners by changing the mold. The corner cutter includes a corner cutter, a corner die-cutting machine, and multiple post-processing machines, which can process the corner guard into the required shape. The slitting and rewinding machine is used to cut large rolls of paper into rolls of a certain size for the corner guard machine.

Paper Corner Board Production Process:

1. Paper hanging part: Determine the number of paper hangers according to the number of paper layers required by the customer.

2. There are many ways to choose from for gluing, such as single-sided gluing, double-sided gluing, spray-type gluing, etc. Generally, transfer-type automatic gluing is used, and the thickness of the glue can be adjusted at will with a scraper.

3. Curling adjustment part: The paper corner board machine uses multiple sets of rollers to adjust each layer of paper. When changing the specifications of the paper corner board, it can be adjusted quickly, conveniently and accurately. The surface paper automatically curls, and the half-wrapped or full-wrapped curling form can be selected. The products produced have beautiful appearance.

4. Forming part: The pressing wheel mold performs high-strength calendering and forming on the paper.

5. Transmission part: The paper corner board machine is driven by a high-power AC motor and equipped with a frequency converter to control the motor operation. The pressing wheel and the motor are connected through a reducer and a transmission shaft. Each pressing wheel rotates synchronously to ensure smooth operation.

6. The paper corner cutting machine equipped with the paper corner board machine is pneumatic, using high-hardness sharp steel blades for cutting, accurate and stable cutting, and smooth and beautiful cutting surface.

7. Data processing: The paper corner board machine uses a PLC central processing system to control the main machine action, and a turret-type length transmitter detects the length, with accurate positioning, automatic length counting, and good cutting synchronization performance. The pneumatic and hydraulic types use three-stage workbenches to control the cutting process, and the panel is centrally operated. The servo type uses an LCD touch screen for data input, and the CNC motor drives the knife holder for positioning, with good cutting synchronization and high precision.

Paper Corner Board Machine Accessories

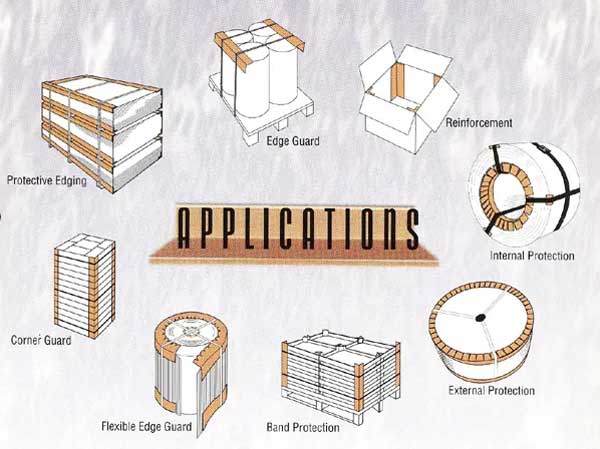

In addition to the paper corner board machine, you also need a paper edge protector cutting machine and a paper slitting and rewinding machine, which belong to post-processing and pre-processing respectively. Paper edge protector rewinder is used to cut V-shaped protectors into smaller pieces, while die cutters are used to cut different shapes as needed. Paper slitting rewinder is used to cut large rolls of paper into rolls of suitable smaller widths, which are then rewound into smaller rolls to make paper edge protectors.

CASES:

I would like to share another interesting case where we helped one of their customers save expensive material and labor costs.

“This customer produces bulk heavy-duty laminated film rolls with a diameter of 42 inches and a height of 48 inches. To protect these expensive rolls, they use wooden crates to secure the goods. However, they wanted to eliminate the expensive wooden crates and contacted us for a solution. After careful investigation, we decided to replace the wooden crates with curved paper corner protectors, which are placed around the outer diameter of the roll to protect the edges. Since the rolls are placed on pallets, we wrap them around the circumference of the roll while gripping the pallet. By using the recommended paper corner board machine, our customer was able to completely remove the wooden crates during shipping, which saved them a lot of time preparing crates. They also got fully encapsulated rolls that were cheaper but better protected”.

The newly upgraded paper corner board machine is also smarter. It cuts more precisely, minimizing waste. The paper corner board machine can now make corner boards as thin as 2mm, an improvement over the previous 4mm minimum thickness. In addition, the new corner boards can be cut 2 inches short and 400 inches long, providing protection for your cargo, no matter how big or small. To learn more about the benefits of paper corner board machine, please visit us.