Description

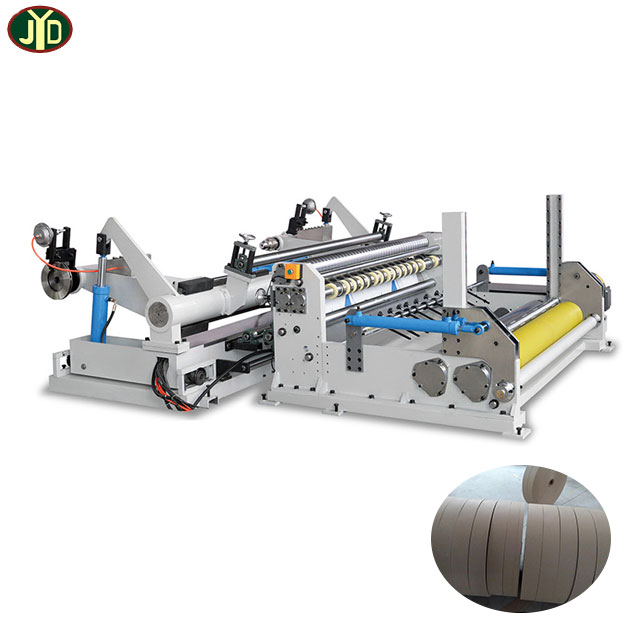

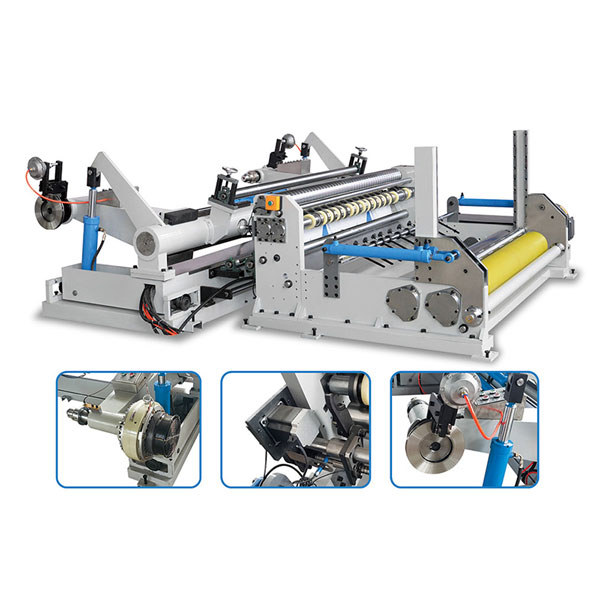

Paper Roll Slitter Machine Introduction

High speed paper roll slitter machine for sale, is a key industrial equipment used to slit large rolls of materials into small rolls and rewind them. Such equipment is widely used in the processing industry of various materials such as paper, film, aluminum foil, non-woven fabrics, textiles, etc. Through precise slitting and efficient rewinding process, slitting and rewinding machines improve production efficiency, optimize material utilization, and meet diverse market needs.

Paper Roll Slitter Machine Parameter

| Model | JYD-1600A | JYD-1600B | JYD-160C | JYD-2500D |

| Width of Paper Roll | 1600mm | 1600mm | 1600-2500mm | 2500mm |

| Base paper diameter | Φ1200mm | Φ1200mm | Φ1200mm | Φ1200mm |

| Winding Diameter | Φ800mm | Φ1200mm | Φ1500mm | Φ1200mm |

| Slitting width | >30(mm) | >35(mm) | >35(mm) | >35(mm) |

| Slitting capability | 80-600g | 80-600g | 80-600g | 80-600g |

| Motor power | 5.5kw | 11kw | 15kw | 22kw |

| Slitting knife | 18pcs | 18pcs | 18pcs | 18pcs |

| Speed of adjust and control | Magnetic force | Frequency control | Frequency control | Frequency control |

| Speed of Slitting | 1-150(m/min) | 1-300(m/min) | 1-300(m/min) | 1-300(m/min) |

| Power input | 380V/220V | 380V/220V | 380V/220V | 380V/220V |

Paper Roll Slitter Machine Advantage

- Applicable base paper weight 80-600g; base paper diameter 1200mm; base paper width 1600mm; slitting width ≥30mm (tools can be configured according to different customer needs).

- The main motor is Shanghai Qiangsu (11kw), with adjustable speed function. It is convenient for adjusting the production speed.

- The inverter is an Anruiji product, which is a well-known domestic brand with high practical value, low failure rate and low rework rate. The motor is controlled by frequency conversion to adjust the machine speed.

- The paper loading method is shaftless hydraulic paper loading, which is stable and replaces the traditional shaft paper loading, making paper loading faster and saving labor. The handle-type electric paper clamp makes the operation more convenient and flexible. At the same time, the dual brakes make the paper pulling force more uniform and powerful, overcoming the loose roll phenomenon caused by insufficient single brake pulling force.

- The independent leveling shaft can reduce the phenomenon of inconsistent tightness of the left and right sides of the skewed paper.

Paper Roll Slitter Machine Application

-

Papermaking industry:

During the papermaking process, large rolls of paper need to be cut into small rolls of different widths for subsequent processing and use. Paper roll slitter machine can complete this task quickly and accurately.

-

Printing industry:

During the printing process, large sheets of printed paper need to be cut into sizes suitable for printing machines. High speed paper roll slitter machine can accurately cut paper according to the specifications of the printing machine.

-

Packaging industry:

During the packaging process, wide packaging films or plastic bags need to be cut into appropriate lengths and widths.

-

Plastic industry:

During the plastic processing process, large pieces of plastic sheets need to be cut into small pieces for subsequent processing and use.

-

Electronics industry:

In the electronics industry, a large amount of tape is needed. High speed paper roll slitter machine can cut large rolls of tape into small rolls for easy use.

-

Textile industry:

In the textile industry, a large amount of cloth is needed.High speed paper roll slitter machine can cut large rolls of cloth into small rolls for easy use.

Paper Roll Slitter Machine Operation Process:

-

Set parameters

Before operation, you need to set the parameters according to the width, thickness and other parameters of the required material. Turn on the power of the High speed roll slitter machine, enter the setting interface, and set the correct material width, thickness, tension and other parameters. If you are not familiar with the parameter setting, you can refer to the machine’s operating manual.

-

Loading materials

Lay the material to be cut or rewound flat on the loading platform of the High speed paper roll slitter machine, and adjust the position so that it is aligned with the cutting or rewinding tool of the machine.

-

Adjust the position

Adjust the position and spacing of the cutting or rewinding tool to ensure accurate cutting or rewinding of the material. Use the adjustment handle or button on the High speed paper roll slitter machine to adjust.

-

Turn on the machine

After confirming that the material and tool positions are correct, turn on the High speed paper roll slitter machine.

-

Adjust the speed

According to the type and thickness of the material, adjust the speed of the High speed paper roll slitter machine to ensure the quality of cutting or rewinding. Too fast speed may cause the material to be torn or not smooth.

-

Collect materials

After completing a cutting or rewinding, collect the material in time. If the High speed paper roll slitter machine is equipped with an automatic collection device, the material can be collected directly into the collection device, otherwise it needs to be collected manually.

-

Safe operation

During the operation, you need to pay attention to the safe use of the High speed paper roll slitter machine. Before cutting or rewinding, you should confirm that the machine’s cutter and swing arm and other parts are not loose or faulty. When operating, you should wear safety protection equipment and be careful to avoid contact with the cutter or other moving parts with your hands.