The shaftless paper tube cutting machine is quite different from the ordinary paper core cutter in structure and cutting accuracy, and is suitable for different application requirements. The following are their main differences:

1. Structural design

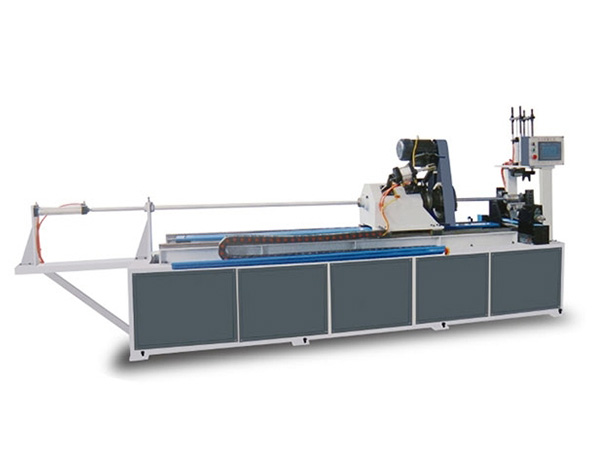

Shaftless paper tube cutting machine: The shaftless precision cutting machine adopts a shaftless design. The pipe is fixed and pushed to rotate by an electric clamping and transmission mechanism. It usually has higher flexibility and can adapt to the cutting of pipes of different diameters and lengths.

Ordinary paper core cutter: Ordinary pipe cutting machines usually adopt a shaft design, that is, the pipe needs to be inserted into a fixed shaft during cutting. It has high stability, but poor adaptability to pipes of different specifications.

2. Cutting accuracy

Shaftless paper tube cutting machine: Due to its shaftless design, it is equipped with a more sophisticated CNC system and guide rails, which can perform high-precision cutting, and is suitable for scenes that require high-precision and high-quality paper tube or metal tube cutting.

Ordinary paper core cutter: The cutting accuracy of ordinary pipe cutting machines is relatively low, and it is suitable for occasions where precision is not required. It is suitable for cutting low-precision products such as general paper tubes and PVC tubes.

3. Operation and adjustment

Shaftless paper tube cutting machine: flexible adjustment, suitable for frequent replacement of pipe cutting of different specifications, with a high degree of automation, generally equipped with CNC system, simple operation.

Ordinary paper core cutter: the size of the axis and other components needs to be manually adjusted to adapt to pipes of different specifications. The operation is relatively cumbersome and the degree of automation is low.

4. Scope of application

Shaftless paper tube cutting machine: suitable for materials such as paper tubes, aluminum tubes, stainless steel tubes, etc. with high precision cutting requirements, widely used in electronics, packaging, aviation and other industries with high precision requirements.

Ordinary paper core cutter: suitable for materials such as plastic tubes and paper tubes with low requirements, mainly used in packaging, printing and other industries.

5. Cost

Shaftless paper tube cutting machine: high cost, but provides higher precision and efficiency, suitable for medium and large enterprises and enterprises with high requirements for cutting quality.

Ordinary paper core cutter: cheap price, suitable for small enterprises and cost-sensitive scenarios, suitable for occasions with low requirements for cutting quality.

Summary

Shaftless paper tube cutting machine has more advantages in precision, operational flexibility and adaptability, while ordinary pipe cutting machine is more economical and suitable for general needs.