Description

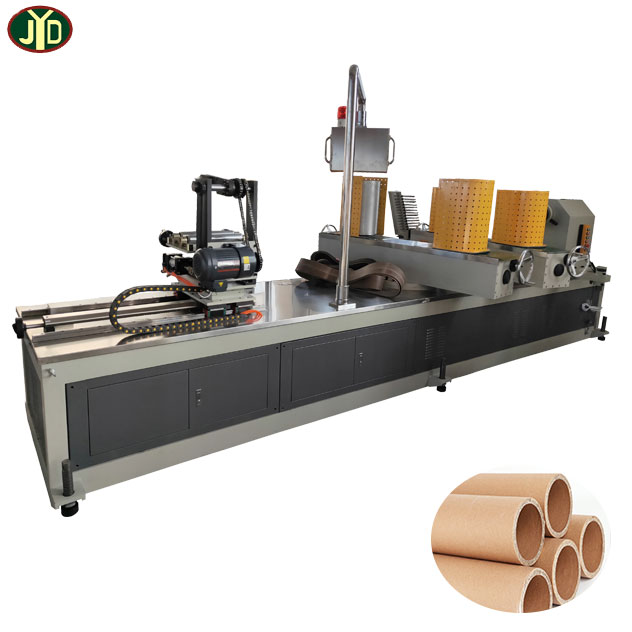

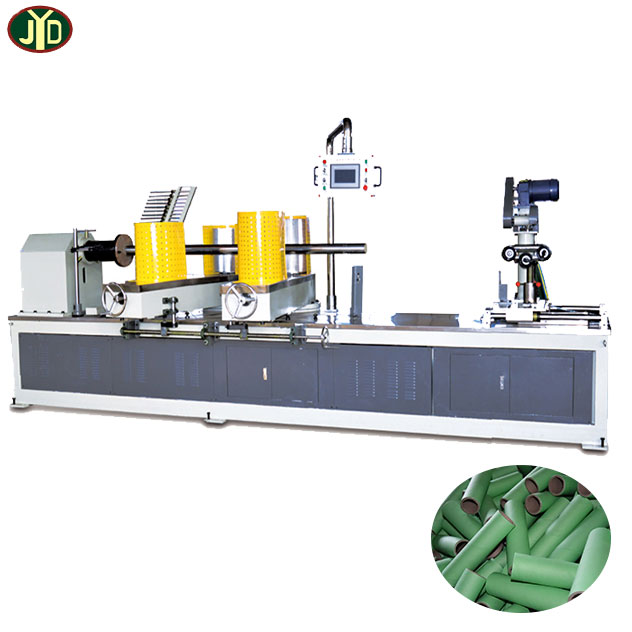

Fireworks Paper Tube Making Machine Introduction

The fireworks paper tube making machine revolutionizes production processes by automating the fabrication of paper cores and tubes. This versatile equipment seamlessly transforms raw paper material into uniform tubes, offering precision and efficiency. Its automated features streamline operations, reducing production time and increasing output capacity. With user-friendly controls and robust safety measures, it ensures seamless operation and high-quality results. Cost-effective and adaptable to various industry needs, this machine is a valuable asset for businesses seeking to optimize their manufacturing processes.

Fireworks Paper Tube Making Machine Parameters

| Model | JYD-500 | JYD-350 | JYD-200 |

| Number of papers | 3-25 layers | 3-25layers | 3-25 layers |

| Inner diameter of paper tube | 40-500(mm) | 76-605mm | 30-200(mm) |

| Thickness of paper tube | 2-15(mm) | 2-10(mm) | 2-15(mm) |

| Tube rolling speed | 0-25(m/min) | 0-20(m/min) | 0-20(m/min) |

| Fixed length mode | CNC control | Light control | Light Control |

| Winding head | No resistance 4 heads | 2 heads | 4 heads |

| Cutting method | CNC Automatic Tracking for Cutting | Circular knife CNC automatic | Single knife cutting |

| Fixed method of core mold | Flange tightening | Flange tightening | Flange tighteningl |

| Gluing method | Double-sided glue | Double-sided glue | Double-sided glue |

| Control method | Frequency control | Frequency control | Frequency control |

| Input voltage | 380V/220V | 380V/220V | 380V/220V |

| Number of operators | 1-3 persons | 1-3 people | 1-3 people |

Fireworks Paper Tube Making Machine Supporting Equipment:

Embossing machine

Gluing machine: pneumatic gluing machine, single-sided gluing machine

Automatic punching machine

Printing rewinding machine

(Choose according to your needs, we can also provide you with a perfect solution)

Fireworks Paper Tube Making Machine Advantages

-

High-speed production:

The fireworks paper tube making machine adopts advanced automated production technology, which can achieve high-speed continuous production. No matter how large your production needs are, our machine can easily cope with it and ensure the stable and efficient operation of your production line.

-

Precision cutting:

Through the control of the precise CNC system, our paper core tube making machine can achieve high-precision cutting with an error range of only ±0.1mm. Whether it is the diameter, length or wall thickness of the paper tube, our machine can ensure that the size of each paper tube is accurate and consistent to ensure product quality.

-

Multi-functional application:

Our fireworks paper tube making machine supports the production of paper tubes of various specifications and types, and can be applied to the production of paper tubes of different materials (such as paper, plastic, metal) and different diameters (from 20mm to 200mm). You no longer need multiple machines, one machine can cope with multiple production needs.

-

Intelligent operation:

Our fully fireworks paper tube making machine is equipped with an intuitive and friendly human-machine interface, which is easy to operate, easy to learn and use. The fireworks paper tube making machine reduces the workload of operators and improves production efficiency.

5.Customized service:

We provide customized service, customize the machine configuration and functions according to the specific needs of customers, and ensure that the machine fully meets your production requirements.

Fireworks Paper Tube Making Machine Application

The paper core tube making machine finds application across various industries:

1.Packaging:

Produces cardboard cores and eco-friendly packaging solutions for products like textiles, cosmetics, and food items.

2.Textile Manufacturing:

Essential for yarn winding and textile processing operations in textile mills.

3.Construction:

Used in forming concrete columns and dispensing adhesive sealants.

4.Paper Manufacturing:

Produces cores for paper rolls, facilitating handling and storage during transportation.

5.Automotive Engineering:

Utilized in components like exhaust systems, air filters, and wiring harnesses.